- #How a computerized maintenance management system how to#

- #How a computerized maintenance management system software#

#How a computerized maintenance management system software#

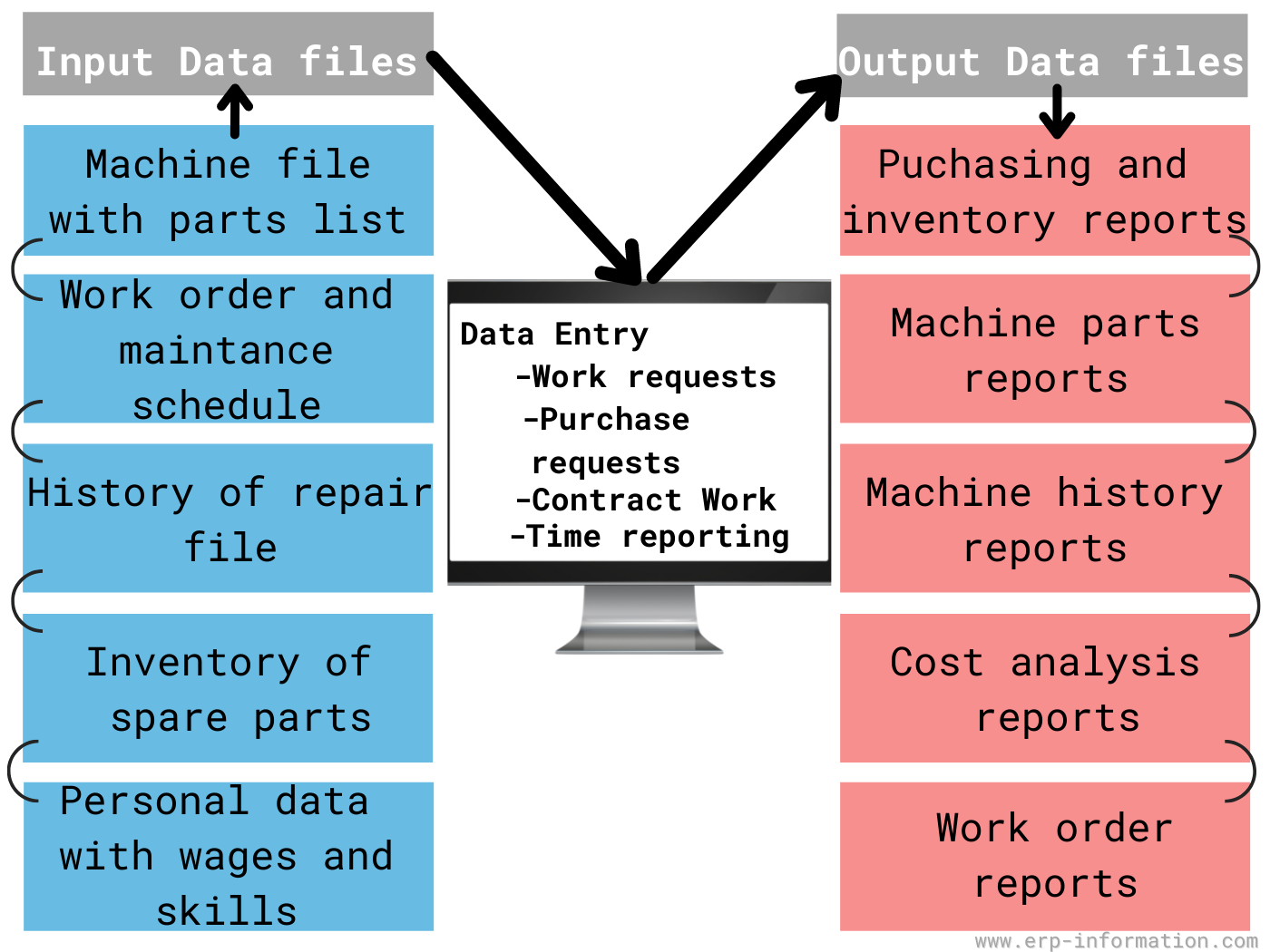

This is just a high-level view of what modern, cloud-based CMMS software can help your maintenance do. CMMS software helps you schedule, organize, track, and optimize your maintenance in one place with just a few clicks. There’s more pressure on maintenance teams than ever before to maximize production while reducing costs, not to mention maintaining good employee morale.This is where CMMS software can help you. Unfortunately, these approaches don’t cut it anymore as competition in the market increases and teams face the demands for higher production quotas. Until recently, most maintenance teams relied on Excel spreadsheets, pen and paper, and legacy maintenance software to get the job done. It is one more way to get added efficiency from the software.Maintenance strategies have evolved dramatically over the years, with a shift in understanding of how preventive maintenance can extend the life of assets, increase productivity, improve overall efficiency, and reduce maintenance costs in ways reactive maintenance can’t.īut the tools to manage them haven’t always kept up. Just 9% used them to schedule and disseminate information to their teams.Ī CMMS solution makes it simpler for technicians to stay in touch and learn about their next project without returning to the main office. It was much more common to use them as a way to stay in touch as 23% of teams reported using them in that way. Just 8% of maintenance teams were using mobile devices for maintenance tasks in 2020. Handheld mobile devices have not been as popular in maintenance management as one might think, but part of that is because the software has been challenging to use on these devices until recently.Īs mobile devices become an essential part of everyday life, technology is catching up and improving on these devices. Some CMMS now includes Power BI natively within the software so you can create visualizations to better understand maintenance needs and show a visual history with the software. And analytics and visualization tools keep improving to make it simpler to showcase the value the software provides. The ability to bring in past maintenance data to inform future maintenance to avoid breakdowns is astounding. Showing the value of CMMS and that it is worth the expense is getting simpler thanks to AI and other analytics tools. Big data tools and analytics are essential Attracting the best talent in the industry might mean using the best technology.Ģ. And many new workers might expect that CMMS is in place and feel resistant toward old ways of handling maintenance scheduling, such as pen and paper or spreadsheet management.

#How a computerized maintenance management system how to#

This means that as companies hire new maintenance technicians, they likely know what CMMS is and how to use it. As more companies realize the power of preventative maintenance and a tool to manage all aspects of that maintenance, the CMMS market is expected to grow 8.58% year over year from 2020 to 2027.74% of CMMS users state that they think the tool improves their productivity.The top challenge facing maintenance teams is hiring and retaining individuals, making careful scheduling and planning of resources essential.The average time they spend on completing the maintenance is just 19 hours. 34% of facilities spend more than 30 hours per week scheduling maintenance.

39% of maintenance managers are using CMMS, while 28% are using spreadsheets and 21% are still using pen and paper.Here’s a look at some key industry statistics to help set the stage for what you’ll see in 2022. CMMS adoption continues to increase as maintenance teams look for ways to improve preventative maintenance and maximize their resources.

0 kommentar(er)

0 kommentar(er)